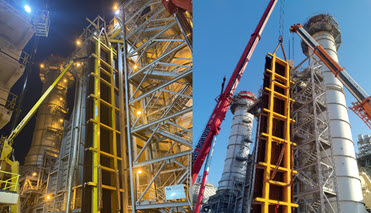

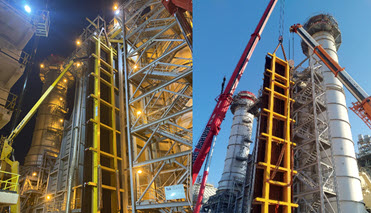

Harp Replacement Project: HRSG #1 & #2

Client: AES Jordan PSC

Methods: PT, MT, UTT, UT, RT, VT, WQT, WPS

For the Harp Replacement on Heat Recovery Steam Generators (HRSG) Units 1 & 2, Synergy managed the total quality lifecycle of the high-pressure tube modules. HRSG harps are subjected to extreme thermal cycling and high-velocity gas flow, requiring flawless welding and material integrity to prevent creep and fatigue failure.

The Technical Edge: From Qualification to Commissioning

We provided end-to-end oversight, ensuring that every new component was integrated into the steam cycle with surgical precision:

* Welding Engineering (WPS & WQT): Before fabrication, we developed and verified Welding Procedure Specifications (WPS) for specialized alloy steels. We then conducted Welder Qualification Tests (WQT) to ensure all technicians were certified for the complex, restricted-access welds required by harp configurations.

* Volumetric Inspection (RT & UT): We utilized Radiographic Testing (RT) for the definitive certification of tube-to-header welds. This was complemented by Ultrasonic Testing (UT) to ensure the internal soundness of thicker structural connections.

* Surface & Integrity Mapping (MT, PT, UTT): * MT & PT were used to verify that all surface and near-surface areas were free of thermal stress cracks.

* UTT was performed on the new modules to establish a baseline for future erosion/corrosion monitoring.

* Visual Audit (VT): Continuous visual monitoring was maintained throughout the installation to verify alignment, fit-up, and expansion joint integrity.

The Result:

Synergy’s rigorous multi-method approach guaranteed that the replacement harps were installed to original equipment manufacturer (OEM) standards. By managing the process from the initial WPS through to final RT/UT certification, we provided AES Jordan with a fully validated system, restoring the HRSG units to peak efficiency and significantly reducing the risk of future tube leaks.